1. Clean the Machine Regularly. 2. Lubricate Moving Parts. 3. Check and Tighten Screws and Bolts. 4. Inspect Needles and Sinkers. 5. Check Tension and Alignment...

1. Clean and Lubricate Regularly. 2. Check and Adjust Tension Mechanisms. 3. Inspect Needles and Sinkers. 4. Check Timing and Belts. 5. Monitor Temperature and ...

Introduction. 1. Cleaning the Machine. 2. Lubricating Moving Parts. 3. Checking Needles and Hooks. 4. Adjusting Tension. 5. Regular Inspections. 6. Choosing the...

1. Increased Production Efficiency. 2. Versatile Stitch Patterns. 3. Seamless Integration with CAD Software. 4. Precision and Consistency. 5. Reduced Waste and ...

1. Clean Regularly. 2. Inspect for Damage. 3. Store Properly. 4. Avoid Excessive Tension. 5. Use Proper Yarn. 6. Lubricate Moving Parts. 7. Avoid Excessive Heat...

1. Regular Cleaning and Lubrication. 2. Inspection of Needles and Sinkers. 3. Tension Adjustment. 4. Checking and Replacing Belts. 5. Calibration of Gauges. 6. ...

1. Cleaning and Lubrication. 2. Needle Maintenance. 3. Check Tension and Gauges. 4. Belt and Motor Maintenance. 5. Regular Calibration. 6. Inspection of Electro...

1. Clean the Machine Regularly. 2. Lubricate Moving Parts. 3. Check and Adjust Tension. 4. Inspect Needles and Sinkers. 5. Maintain Proper Needle Alignment. 6. ...

1. Knitting. 2. Shaping. 3. Patterning. 4. Ribbing. 5. Color Changing. 6. Tension Control. 7. Speed Adjustment. 8. Automation. Conclusion....

Introduction. 1. Loop Formation. 2. Pattern Creation. 3. Yarn Feeding. 4. Speed and Productivity. 5. Automation and Control. 6. Versatility. 7. Energy Efficienc...

1. Automatic Yarn Feeding. 2. Multiple Stitch Patterns. 3. Adjustable Tension. 4. Speed Control. 5. Circular and Flat Knitting. 6. Easy Stitch Correction. 7. Bu...

1. Yarn Feeding. 2. Fabric Formation. 3. Stitch Selection. 4. Fabric Tension Control. 5. Diameter Adjustment. 6. Fabric Take-Down. 7. Speed Control. 8. Quality ...

1. Yarn Feeding. 2. Stitch Formation. 3. Pattern Programming. 4. Size and Shape Customization. 5. Seamless Construction. 6. Quality Control. 7. Speed and Effici...

1. Fabric Production. 2. Pattern Creation. 3. Seamless Construction. 4. Productivity and Efficiency. 5. Versatility in Yarns. 6. Knit Structure Variation. 7. Qu...

Introduction. 1. Gather Your Equipment. 2. Assemble and Secure the Machine. 3. Threading the Yarn. 4. Casting-On Stitches. 5. Setting Up the Stitch Pattern. 6. ...

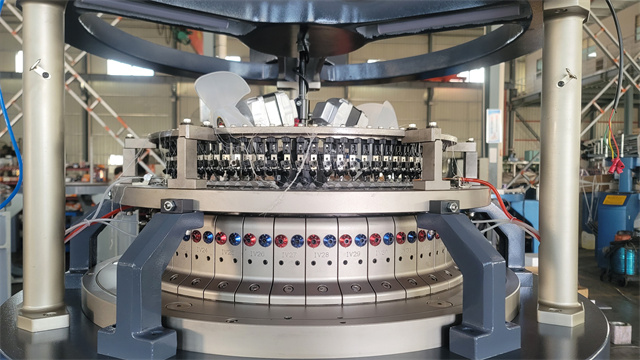

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.