Introduction. 1. Regular Cleaning. 2. Lubrication. 3. Inspection and Replacement of Parts. 4. Tension Adjustment. 5. Alignment and Calibration. 6. Proper Yarn H...

1. Regular Cleaning and Lubrication. 2. Inspection and Replacement of Parts. 3. Tension Adjustment. 4. Alignment and Calibration. 5. Regular Maintenance of Elec...

1. Clean the Machine Regularly. 2. Lubricate Moving Parts. 3. Check and Replace Needles. 4. Adjust Tension Settings. 5. Keep the Machine Covered. 6. Store in a ...

Introduction. 1. Regular Cleaning. 2. Lubrication. 3. Needle Maintenance. 4. Tension Adjustment. 5. Check for Loose Screws. 6. Storage. 7. Professional Servicin...

1. Cleaning the Machine Regularly. 2. Lubricating Moving Parts. 3. Inspecting Needles and Hooks. 4. Checking Tensions and Gauges. 5. Calibrating the Yarn Feeder...

Introduction. Market Analysis. Technical Features. Conclusion....

1. Clean the Machine Regularly. 2. Lubricate Moving Parts. 3. Check and Adjust Tension. 4. Replace Needles and Hooks When Necessary. 5. Store the Machine Proper...

1. Clean the Machine Regularly. 2. Lubricate Moving Parts. 3. Check Tension and Alignment. 4. Replace Needles and Parts as Needed. 5. Keep the Workspace Organiz...

1. Clean Your Machine Regularly. 2. Lubricate Moving Parts. 3. Check and Adjust Tension. 4. Replace Needles and Hooks. 5. Use High-Quality Yarns. 6. Store Prope...

1. Regular Cleaning. 2. Lubrication. 3. Check for Loose Screws and Bolts. 4. Replace Worn or Damaged Needles. 5. Keep the Machine Covered. 6. Avoid Excessive Te...

1. Introduction. 2. Regular Cleaning. 3. Lubrication. 4. Needle Maintenance. 5. Tension Adjustment. 6. Check and Replace Parts. 7. Training and Education. 8. Pe...

...

...

1. Keep the Needles Clean. 2. Lubricate the Needles. 3. Check Needle Alignment. 4. Replace Damaged Needles. 5. Avoid Excessive Needle Stress. 6. Store Needles P...

1. Regular Cleaning. 2. Lubrication. 3. Tension Adjustment. 4. Needle Maintenance. 5. Belt Replacement. 6. Electrical System Maintenance. 7. Training and Educat...

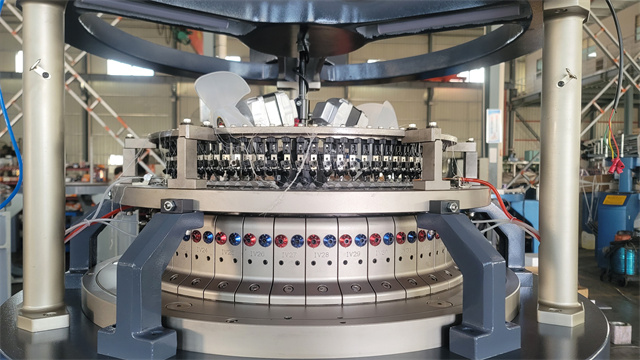

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.