Introduction. 1. Understanding the Machine. 2. Proper Machine Setup. 3. Programming Patterns. 4. Ensuring Quality Control. 5. Troubleshooting Common Issues. 6. ...

1. Understanding the Features of the Fukuhara Knitting Machine. 2. Setting Up the Fukuhara Knitting Machine. 3. Operating the Fukuhara Knitting Machine. 4. Trou...

Introduction. 1. Understanding the Machine Components. 2. Yarn Selection and Preparation. 3. Threading the Machine. 4. Setting the Machine Tension. 5. Mastering...

Introduction. Understanding Circular Knitting Machines. Choosing the Right Yarn. Setting Up the Machine. Mastering Stitch Patterns. Maintaining Consistent Tensi...

1. Market Overview. 2. Competitive Landscape. 3. Product Portfolio. 4. Market Segmentation. 5. Market Trends. 6. Future Outlook. 7. Challenges. 8. Conclusion....

1. Regular Cleaning. 2. Lubrication. 3. Needle Maintenance. 4. Check Tension Units. 5. Monitor Yarn Feeders. 6. Conduct Routine Inspections. 7. Follow Manufactu...

Introduction. 1. Cleaning and Dusting. 2. Lubrication and Oil Change. 3. Inspection of Needles and Sinkers. 4. Tension Adjustment. 5. Belt and Gear Inspection. ...

Introduction. 1. Regular Cleaning. 2. Lubrication. 3. Needle Maintenance. 4. Tension Adjustment. 5. Belt Replacement. 6. Electrical Connections. 7. Training and...

1. Cleaning the Machine. 2. Lubrication. 3. Needle Maintenance. 4. Tension Adjustment. 5. Regular Inspections. 6. Avoiding Excessive Strain. 7. Storage and Prot...

1. Regular Cleaning and Lubrication. 2. Inspection and Replacement of Parts. 3. Tension Adjustment. 4. Needle Maintenance. 5. Yarn Feeders and Guides. 6. Belt a...

Introduction. 1. Regular Cleaning. 2. Lubrication. 3. Needle Maintenance. 4. Tension Adjustment. 5. Regular Maintenance Schedule. 6. Training and Education. 7. ...

1. Regular Cleaning. 2. Lubrication. 3. Inspection of Needles and Sinkers. 4. Tension Adjustment. 5. Belt and Gear Inspection. 6. Electronic Component Maintenan...

1. Cleaning the Machine. 2. Lubricating the Moving Parts. 3. Checking and Adjusting Tension. 4. Inspecting and Replacing Needles. 5. Cleaning and Oil the Sinker...

Introduction. 1. Cleaning and Lubrication. 2. Regular Inspection. 3. Needle Maintenance. 4. Tension Adjustment. 5. Training and Operator Knowledge. 6. Electrica...

Introduction. 1. Regular Cleaning. 2. Lubrication. 3. Inspection of Needles and Sinkers. 4. Tension Adjustment. 5. Calibration and Alignment. 6. Electrical Syst...

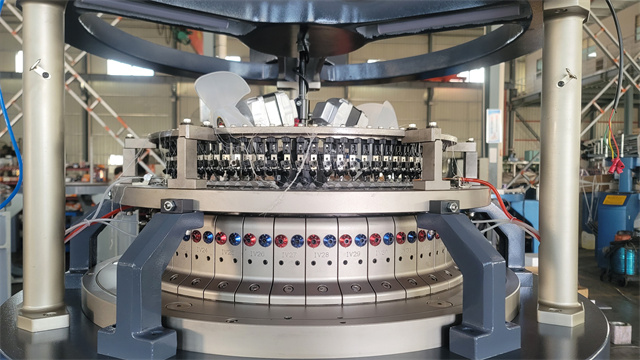

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.