1. Choose the Right Location. 2. Check Power Supply Requirements. 3. Assembly of Machine Parts. 4. Lubrication and Maintenance. 5. Thread Tension and Adjustment...

1. Prepare the Installation Area. 2. Verify Machine Components. 3. Follow Safety Procedures. 4. Establish Proper Alignment. 5. Connect Power and Utilities. 6. T...

1. Unboxing and Checking Contents. 2. Assembling the Main Knitting Unit. 3. Attaching the Row Counter. 4. Setting up the Table Clamp. 5. Attaching the Yarn Guid...

1. Unboxing and Inspection. 2. Assembly of the Main Frame. 3. Attaching Circular Knitting Needles. 4. Setting up Yarn Holders and Tensioner. 5. Threading the Ya...

1. Introduction. 2. Unpacking and Inspection. 3. Site Preparation. 4. Machine Assembly. 5. Electrical Connections. 6. Machine Calibration. 7. Testing and Troubl...

Introduction. Step 1: Unpacking. Step 2: Assembly. Step 3: Power Connection. Step 4: Thread Installation. Step 5: Needle Selection. Step 6: Machine Settings. St...

1. Unpacking the Machine. 2. Assembling the Machine. 3. Connecting Power and Cables. 4. Installing the Software. 5. Calibrating the Machine. 6. Adding Yarn and ...

Introduction. Step 1: Unpacking and Inspection. Step 2: Setting Up the Main Body. Step 3: Attaching the Carriage. Step 4: Installing the Tension Mast. Step 5: M...

1. Unpack and Inspect. 2. Prepare the Workspace. 3. Connect Power Supply. 4. Assemble the Machine. 5. Install Necessary Software. 6. Thread and Adjust. 7. Condu...

Introduction. Preparation. Equipment Setup. Electrical Connections. Calibration. Safety Measures. Testing and Troubleshooting. Maintenance and Cleaning. Conclus...

Introduction. Step 1: Unpacking and Inspection. Step 2: Assembling the Stand. Step 3: Attaching the Machine to the Stand. Step 4: Connecting Power Supply. Step ...

Introduction. 1. Pre-installation Preparation. 2. Unpacking and Inspection. 3. Assembly of Components. 4. Electrical and Mechanical Connections. 5. Calibration ...

1. Prepare the Work Area. 2. Secure the Machine. 3. Remove the Old Cylinder. 4. Clean the Machine. 5. Install the New Cylinder. 6. Test the Cylinder. 7. Reassem...

Introduction. Step 1: Unboxing. Step 2: Assembling the Machine. Step 3: Connecting the Power. Step 4: Threading the Yarn. Step 5: Setting Up the Controls. Step ...

1. Unpacking the Machine. 2. Positioning the Machine. 3. Connecting Power Supply. 4. Installing Needles and Yarn Feeder. 5. Adjusting Tension and Stitch Length....

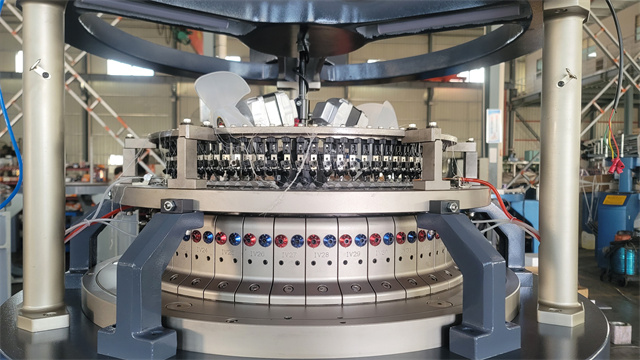

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.