Introduction. 1. High-Speed Operation. 2. Multiple Needle Beds. 3. Electronic Control System. 4. Automatic Yarn Feeding. 5. Quick Changeover. 6. Energy Efficien...

1. Double Needle Beds. 2. Central Stitch Control. 3. Cam Systems. 4. Multiple Feeder Options. 5. Electronic Control Systems. 6. Auto Stop and Error Detection. 7...

1. Diameter and Gauge. 2. Needle Selection System. 3. Cam System. 4. Yarn Feeders. 5. Fabric Takedown System. 6. Electronic Control System. 7. Auto Stop and Err...

1. Needle Bed. 2. Knitting Needles. 3. Yarn Feeder. 4. Fabric Take-Up System. 5. Control Panel. 6. Lubrication System. 7. Auto Stop and Error Detection. 8. Ener...

1. High-Speed Rotation:. 2. Multiple Feeder Systems:. 3. Electronic Jacquard:. 4. Automatic Lubrication System:. 5. Multi-Cylinder Technology:. 6. Touchscreen C...

Introduction. 1. Needle Arrangement. 2. Cylinder Diameter. 3. Needle Gauges. 4. Stitch Types. 5. Mechanisms for Needle Movement. 6. Cylinder Materials. 7. Cylin...

Introduction. Step 1: Gather the Required Tools. Step 2: Prepare the Machine. Step 3: Attach the Needle Holder. Step 4: Insert the Needles. Step 5: Check Needle...

Introduction. 1. Unpacking and Inspection. 2. Choosing the Right Location. 3. Assembling the Machine Frame. 4. Installing Needles and Yarn Carriers. 5. Setting ...

Introduction. 1. Unpacking and Inspection. 2. Assembling the Machine Frame. 3. Installing the Carriage. 4. Mounting the Needles. 5. Connecting Yarn Holders. 6. ...

1. Needle Materials. 2. Needle Geometry. 3. Needle Manufacturing Techniques. 4. Needle Sensors and Monitoring Systems. 5. Needle Flexibility and Adjustability. ...

1. Needle Selection System. 2. Multiple Feeders. 3. Automatic Stitch Control. 4. Fabric Monitoring System. 5. Computerized Control System. 6. Cylinder and Dial ...

1. Computerized Control System. 2. Multiple Yarn Feeding Options. 3. Advanced Needle Selection Mechanism. 4. Jacquard Knitting Capability. 5. Stitch Transfer an...

1. Machine Setup. 2. Yarn and Needle Selection. 3. Tension Adjustment. 4. Machine Calibration. 5. Monitoring and Maintenance. 6. Troubleshooting Common Issues. ...

Introduction. 1. Machine Setup. 2. Yarn Selection. 3. Programming. 4. Machine Operation. 5. Maintenance. 6. Troubleshooting. 7. Safety Considerations. Conclusio...

Introduction. 1. Machine Overview. 2. Preparing the Machine for Operation. 3. Yarn Feeding and Tensioning. 4. Needle Selection and Replacement. 5. Fabric Inspec...

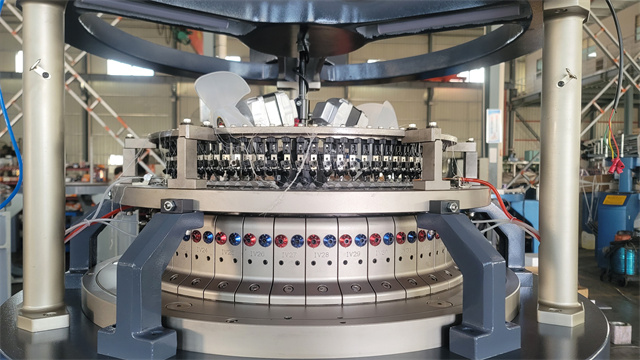

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.