Introduction. 1. Machine Type. 2. Machine Gauge. 3. Machine Diameter. 4. Speed and Productivity. 5. Additional Features. 6. Machine Reliability and Support. 7. ...

1. Machine Type. 2. Knitting Speed. 3. Stitch Variety. 4. Yarn Compatibility. 5. Key Features. 6. User-Friendly Interface. 7. Durability and Maintenance. 8. Bud...

Introduction. 1. Consider the Knitting Needle Type. 2. Gauge Compatibility. 3. Machine Size and Portability. 4. Automation and Features. 5. Durability and Longe...

Introduction. 1. Knitwear Manufacturing. 2. Sportswear Production. 3. Home Textiles. 4. Accessories. 5. Medical Textiles. 6. Automotive Textiles. 7. Technical T...

1. Apparel Industry. 2. Sportswear and Activewear. 3. Home Textiles. 4. Automotive Industry. 5. Medical Textiles. 6. Technical Textiles. 7. Footwear Manufacturi...

1. Production of Basic Knitted Fabrics. 2. Seamless Garment Production. 3. Elastic and Stretch Fabrics. 4. Textured and Patterned Fabrics. 5. Jacquard and Intar...

1. Apparel Industry. 2. Sportswear Manufacturing. 3. Home Textiles. 4. Medical Textiles. 5. Automotive Industry. 6. Technical Textiles. 7. Fashion Accessories. ...

1. Textile Industry. 2. Fashion Industry. 3. Medical Textiles. 4. Automotive Industry. 5. Home Furnishings. 6. Sports Industry. 7. Technical Textiles. 8. Non-te...

1. Fashion Industry. 2. Sportswear. 3. Automotive Industry. 4. Medical Textiles. 5. Home Furnishings. 6. Technical Textiles. 7. Accessories. 8. Sustainability. ...

1. Textile Industry. 2. Fashion and Apparel. 3. Automotive Industry. 4. Sports and Outdoor Equipment. 5. Home Furnishings. 6. Medical Textiles. 7. Technical Tex...

Early Manual Knitting Techniques. Invention of the First Automatic Knitting Machine. Integration of Electronic Controls. Introduction of Computerized Knitting M...

1. Fashion Industry. 2. Sports Apparel. 3. Uniform Manufacturing. 4. Children's Apparel. 5. Luxury Knitwear. 6. Eco-Friendly Production. 7. Small-Scale Producti...

1. Increased Efficiency. 2. Precision and Consistency. 3. Versatility in Design. 4. Time and Cost Savings. 5. Enhanced Productivity. 6. Improved Quality Control...

Improved Efficiency. Versatility in Design. Enhanced Comfort and Fit. Cost Efficiency. Increased Durability. Reduced Environmental Impact. Greater Customization...

Advantages of Underwear Knitting Machines. 2. Versatile Fabric Options. 3. Customization Capabilities. 4. Seamless Integration of Features. 5. Waste Reduction. ...

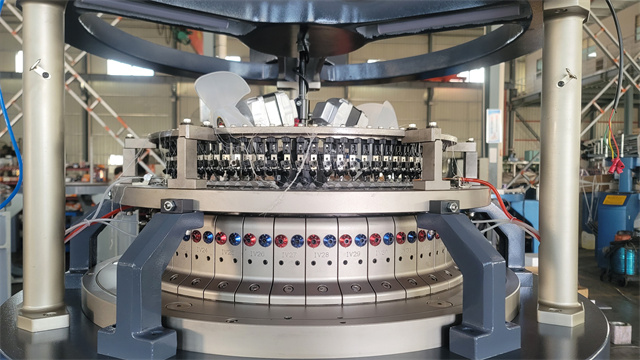

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.