1. Seamless Garments. 2. Accessories. 3. Home Decor. 4. Toys and Amigurumi. 5. Baby Items. 6. Therapy and Rehabilitation. 7. Educational Tool. 8. Small Business...

Introduction. 1. Creating Complex Patterns. 2. Seamless Garment Production. 3. Increased Efficiency. 4. Versatile Fabric Options. 5. Reduced Waste. 6. Automatio...

Introduction. 1. Seamless Construction. 2. Customization and Unique Designs. 3. Efficiency and Speed. 4. Versatility in Material Choices. 5. Sustainable Manufac...

Early Knitting Techniques. Introduction of Mechanical Knitting Machines. Incorporation of Synthetic Fibers. Computerized Knitting Technology. Seamless Knitting ...

1. Fashion Apparel. 2. Active and Performance Wear. 3. Medical Textiles. 4. Automotive Industry. 5. Home Textiles. 6. Industrial and Technical Textiles. 7. Foot...

1. Apparel Industry. 2. Home Textiles. 3. Automotive Industry. 4. Sports and Activewear. 5. Medical Textiles. 6. Technical Textiles. 7. Fashion Accessories. 8. ...

Introduction. 1. Enhanced Design Flexibility. 2. Efficient Production Process. 3. Seamless Comfort and Fit. 4. Customization and Personalization. 5. Sustainable...

1. The Birth of Circular Knitting Machines. 2. Technological Advancements: Cast-Iron to High-Strength Alloys. 3. On-the-Fly Pattern Changes. 4. Automation and D...

The Early Origins. Mechanization and Automation. Technological Innovations. Enhanced Versatility. Efficiency and Sustainability. Digital Integration. Quality an...

Early Developments. Introduction of Circular Knitting Machines. Integration of Jacquard Technology. Advancements in Automation. Innovations in Fabric Quality. V...

Early Manual Designs. Introduction of Automation. Adoption of Electronic Controls. Integration of Computer Technology. Enhancements in Material Handling. Focus ...

Early Development. Mechanical Innovations. Technological Integration. Material Adaptability. Sustainability Initiatives. Automation and Industry 4.0. Global Imp...

The Origins of Circular Knitting. Early Circular Knitting Machines. The Introduction of Automated Circular Knitting Machines. Advancements in Technology. Specia...

1. Cleaning the Machine. 2. Lubrication. 3. Needle Maintenance. 4. Tension Adjustment. 5. Check the Belts and Pulleys. 6. Regular Calibration. 7. Electrical Saf...

Introduction. 1. Understanding the Machine. 2. Preparing the Site. 3. Unboxing and Assembly. 4. Electrical and Mechanical Connections. 5. Calibrating and Testin...

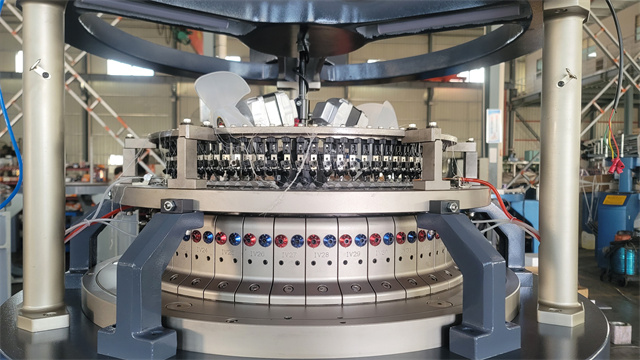

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.