1. Regular Cleaning. 2. Lubrication. 3. Needle Maintenance. 4. Tension Adjustment. 5. Electronic Component Inspection. 6. Belt and Chain Maintenance. 7. Safety ...

Introduction. Step 1: Set Up Your Knitting Machine. Step 2: Thread the Yarn. Step 3: Select the Stitch Pattern. Step 4: Load the Yarn. Step 5: Set the Machine T...

Introduction. 1. Unboxing and Inspection. 2. Choosing the Right Location. 3. Assembling the Machine. 4. Connecting Power and Yarn. 5. Familiarizing Yourself wit...

Introduction. 1. Unboxing and Inspection. 2. Familiarize Yourself with the Manual. 3. Prepare a Suitable Workspace. 4. Assemble the Knitting Machine. 5. Secure ...

Step 1: Unpacking the Machine. Step 2: Assembling the Machine. Step 3: Setting Up the Yarn. Step 4: Adjusting the Machine Settings. Step 5: Loading the Yarn. St...

Step 1: Gather Your Materials. Step 2: Attach the Pegs. Step 3: Cast On. Step 4: Create the Foundation Row. Step 5: Knit the Rows. Step 6: Continue Knitting. St...

1. Understanding the Machine. 2. Selecting the Right Yarn. 3. Preparing the Yarn. 4. Tension Control. 5. Proper Needle Selection. 6. Maintaining the Machine. 7....

Introduction. Step 1: Unpacking and Inspection. Step 2: Assembling the Machine. Step 3: Connecting Power and Utilities. Step 4: Mounting and Aligning Accessorie...

Early Origins of Knitting Interlock Machines. The Industrial Revolution and Mechanization. Rise of Computerized Knitting Interlock Machines. Innovations in Inte...

1. Invention of the Circular Knitting Machine. 2. Introduction of Automated Mechanisms. 3. Advent of Computerized Knitting Machines. 4. Integration of Seamless ...

Early Innovations. Mechanical Advancements. Technological Breakthroughs. Material Compatibility. Environmental Considerations. Global Impact. Adaptation to Digi...

Early Developments of Circular Knitting Machines. The Industrial Revolution and Advancements in Circular Knitting. Innovative Technology in Modern Circular Knit...

1. Knitting Principle. 2. Yarn Feeding Mechanism. 3. Jacquard System. 4. Pattern Design Software. 5. Tension Control. 6. Fabric Inspection System. 7. Production...

Introduction. 1. Machine Capacity. 2. Machine Speed. 3. Machine Versatility. 4. Machine Durability. 5. Machine Technology. 6. Machine After-Sales Support. 7. Ma...

Introduction. 1. Fabric Type. 2. Production Capacity. 3. Machine Features. 4. Budget. 5. After-Sales Support. 6. Reviews and Recommendations. 7. Consider Future...

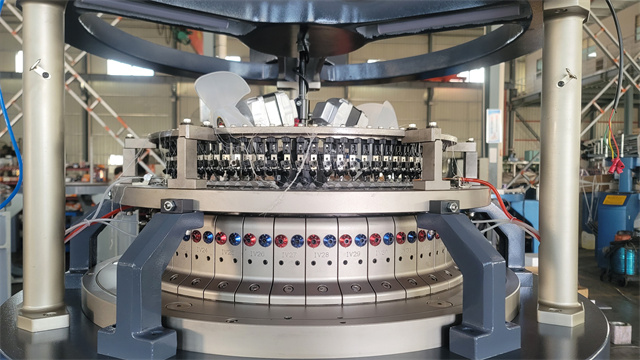

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.