Background:

Our company, XYZ Textile Machinery Co., recently had the privilege of serving a prominent client from Egypt. The client, a leading textile manufacturer in the region, was seeking to enhance their production capabilities in the rib double jersey fabric category. To meet their requirements, we recommended our state-of-the-art Rib Double Jersey Circular Knitting Machine.

Challenges Faced by the Client:The Egyptian client faced several challenges in their quest for better rib double jersey fabric production. Traditional knitting machines they had been using were unable to deliver the exact texture and quality they desired.

Additionally, their existing machines experienced frequent breakdowns, resulting in significant downtime and loss of productivity. To secure their market position and meet the growing demand for rib double jersey fabrics, they needed a reliable and efficient solution.

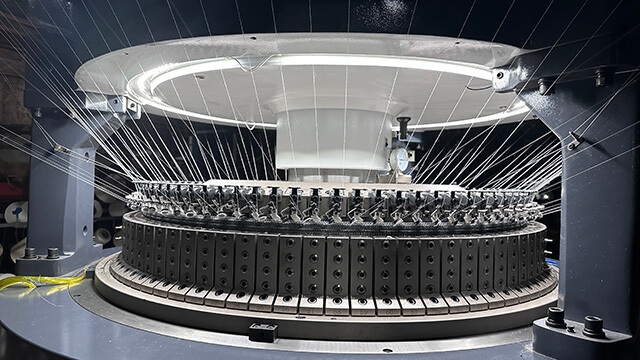

Solution: Rib Double Jersey Circular Knitting MachineAfter carefully assessing the client's requirements and challenges, we proposed our Rib Double Jersey Circular Knitting Machine as the ideal solution.

This advanced machine offered several key features:

1. High Precision and Control:Our Rib Double Jersey Circular Knitting Machine incorporated cutting-edge technology that ensured precise and accurate knitting. It provided increased control over the texture, density, and elasticity of the rib double jersey fabric, enabling consistent and superior quality output.

2. Enhanced Efficiency:With its advanced automation capabilities, the machine significantly reduced manual labor and improved overall efficiency. It featured an intuitive interface and easy-to-use controls, allowing operators to quickly adapt to the machine's functionalities and maximize productivity.

3. Increased Durability and Reliability:Designed with robust and high-quality components, the Rib Double Jersey Circular Knitting Machine offered excellent durability and reliability. Its sturdy construction minimizes the risk of frequent breakdowns, ensuring uninterrupted production and reducing maintenance costs.

Results and Benefits:Implementing the Rib Double Jersey Circular Knitting Machine brought about a remarkable transformation for our Egyptian client.

They experienced several key benefits:

1. Improved Quality:The client achieved the desired texture, density, and elasticity in their rib double jersey fabrics. The machine's precise knitting capabilities resulted in consistent quality output, leading to greater customer satisfaction and increased market demand.

2. Increased Productivity:The advanced automation features of the machine significantly reduced manual labor requirements and optimized production efficiency. This led to a substantial increase in productivity, enabling the client to meet higher volume orders within shorter turnaround times.

3. Cost Savings:The machine's reliability and reduced downtime resulted in cost savings for the client. They no longer had to bear the expenses associated with frequent breakdowns, maintenance, and inefficient manual labor. This allowed them to allocate resources towards further business expansion and innovation.

Conclusion:By implementing our Rib Double Jersey Circular Knitting Machine, our Egyptian client successfully overcame their challenges and achieved significant improvements in their rib double jersey fabric production. The machine's precision, efficiency, and reliability delivered superior quality output, increased productivity, and ensured cost savings.

This case exemplifies how our advanced textile machinery can transform businesses and drive success in the highly competitive textile industry.

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.