Author:Xingfa Knitting MachineFROM:Circular Knitting Machine Manufacturer TIME:2024-03-12

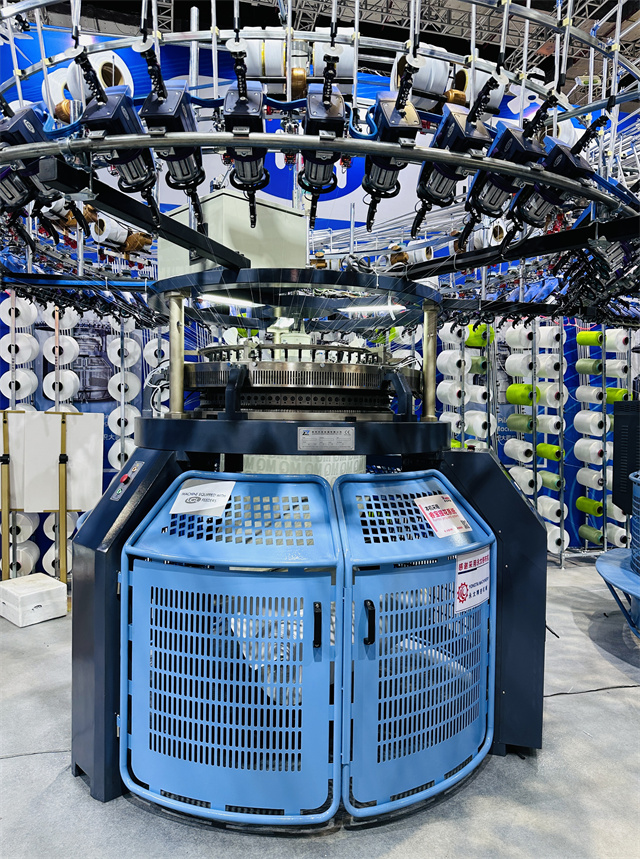

The Evolution of Rib Circular Knitting Machine

The rib circular knitting machine has undergone significant evolution over the years, revolutionizing the textile industry and expanding the possibilities for creating various types of fabrics. From its early inception to the modern advancements, the evolution of this machine has been driven by the continuous pursuit of improved efficiency, versatility, and quality in knitted fabric production.

During the early development of rib circular knitting machines, the focus was on mechanizing the process of creating ribbed fabrics, which were traditionally knitted by hand. The introduction of these machines brought about an increase in production efficiency and consistency in fabric quality, laying the foundation for further advancements in the technology.

As demand for knitted fabrics grew, manufacturers began to innovate the design of rib circular knitting machines to enhance their capabilities. This led to the development of machines with a wider range of gauges, needle arrangements, and stitch control systems, allowing for the production of diverse ribbed fabrics with varying textures and patterns.

The integration of automation and digitization into rib circular knitting machines marked a significant turning point in their evolution. Advanced control systems, electronic actuators, and digital pattern programming enabled greater precision, versatility, and customization in fabric production, streamlining the manufacturing process and reducing material waste.

In response to the growing emphasis on sustainability, modern rib circular knitting machines have evolved to incorporate eco-friendly features. These include energy-efficient operation, reduced water consumption, and the use of recycled materials, aligning with the industry's commitment to sustainable and environmentally conscious manufacturing practices.

Advancements in rib circular knitting machine technology have enabled their adaptation for specialized applications, such as the production of seamless garments, technical textiles, medical textiles, and smart fabrics. The ability to knit complex structures and integrate functional elements has expanded the possibilities for utilizing knitted fabrics across various industries.

The evolution of rib circular knitting machines continues with the integration of smart technologies, including IoT connectivity, data analytics, and predictive maintenance capabilities. These advancements enhance operational efficiency, real-time monitoring, and predictive maintenance, enabling manufacturers to optimize production processes and minimize downtime.

The future of rib circular knitting machines holds promise for further innovation, driven by ongoing research in material science, additive manufacturing, and sustainable technologies. Anticipated developments include the use of advanced composite materials, 3D knitting capabilities, and the integration of artificial intelligence for autonomous production systems, shaping the next phase of evolution for this essential textile manufacturing technology.

In conclusion, the evolution of rib circular knitting machines has been characterized by a continual pursuit of improved performance, versatility, and sustainability. From their early development to the latest technological advancements, these machines have played a pivotal role in shaping the modern textile industry and continue to pave the way for innovative fabric production methods.

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.